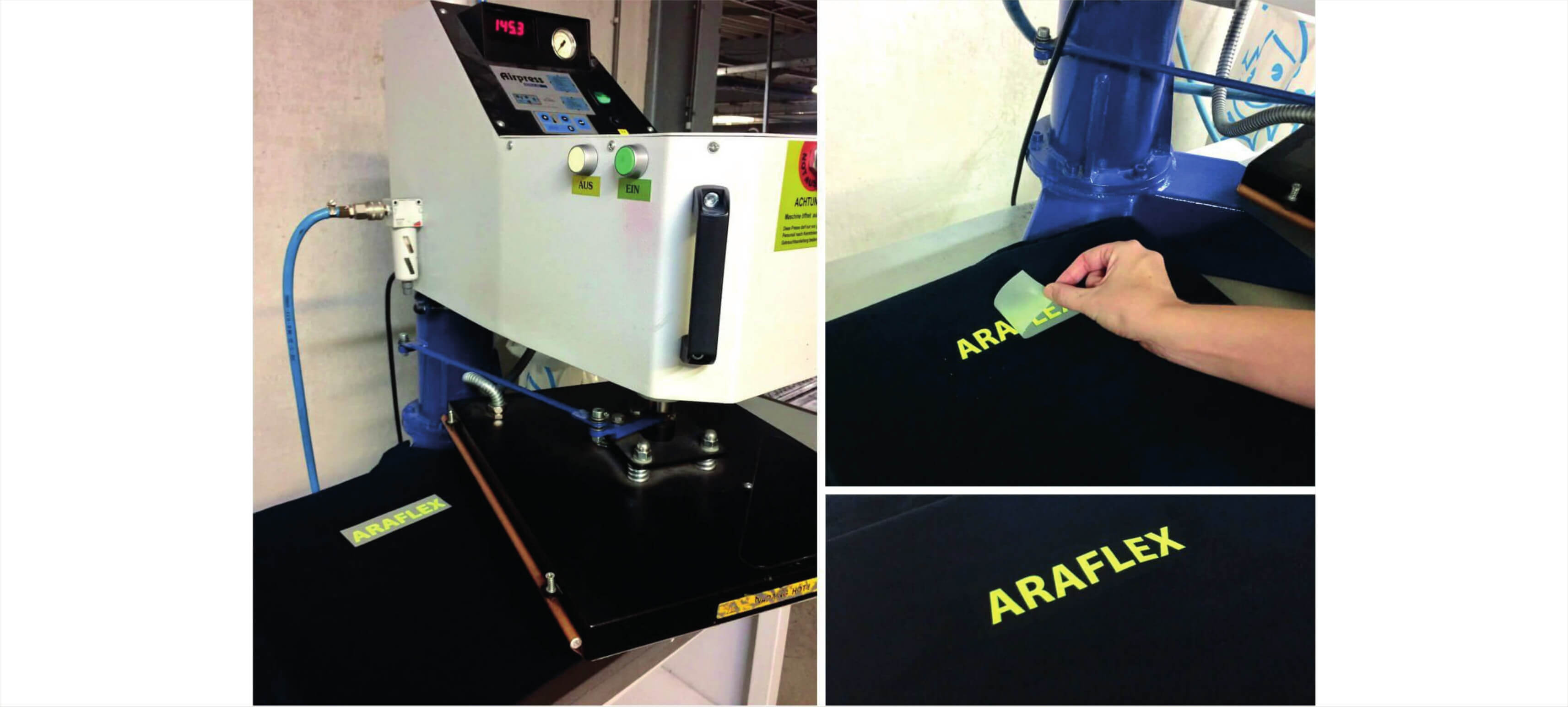

How to work with a heat transfer press

To start printing textile with textile transfers, the first thing you need is a transfer press or heat press. It takes only a small investment in a heat transfer press to do all your print jobs in house, what gives you a great flexibility, and saves efforts and costs in logistics. Textile is a voluminous product to transport, and these transports cause unnecessary extra costs and CO² emissions. When you have your own transfer press and high-quality textile transfers, you can do the printing yourself very easily.

Contact us without obligation to get more info on heat transfers

3 Tips and tricks to work with a transfer press:

The different types of textile transfers each have their own press instructions, it is important to follow these instructions correctly when you apply the prints using your heat press:

-

1. Pressure, temperature and time: the correct settings for your heat press

When applying textile transfers onto garments using a heat press, there are a few parameters which are important to take into account. These are the settings of your transfer press. The first parameter is the pressure, we advise to use a pressure of 3-4 bar. The second parameter is the temperature, most of our heat transfers need a pressing temperature of 145°C, the hot-wash resistant transer prints need to be pressed at 180°C. The third parameter is the duration of the pressing. For all our transfer qualities, the recommended pressing time is 15 seconds.

-

2. When the transfer press opens: hotpeel and coldpeel

Most of our heat transfers are hotpeel quality, which means that you can remove the polyester carrier as soon as the transfer press opens, when the print is still warm. Some qualities are coldpeel, which means that the print had to cool down completely before removing the polyester foil.

-

3. Pre-shrinking and post-pressing under the heat press

For some types of textile it is recommended to pre-shrink the garment under the transfer press before applying the print. Textile such as knitted cotton can shrink under influence of high temperature, for example during washing. By pre-shrinking the textile under the heat press before applying the logo, you can avoid that the printed textile shrinks afterwards, with the risk of the print coming off (because the print does not shrink while the textile does).

When applying textile transfers with a heat press, we recommend to post-press the print during 5 seconds, after removing the polyester carrier. This ensures a good attachment of the transfer print onto the textile, and makes the transparent border of the glue less visible.

Contact us without obligation to get more info on heat transfers

Discover our range of heat transfers for sportswear, workwear and promowear, and start printing immediately: